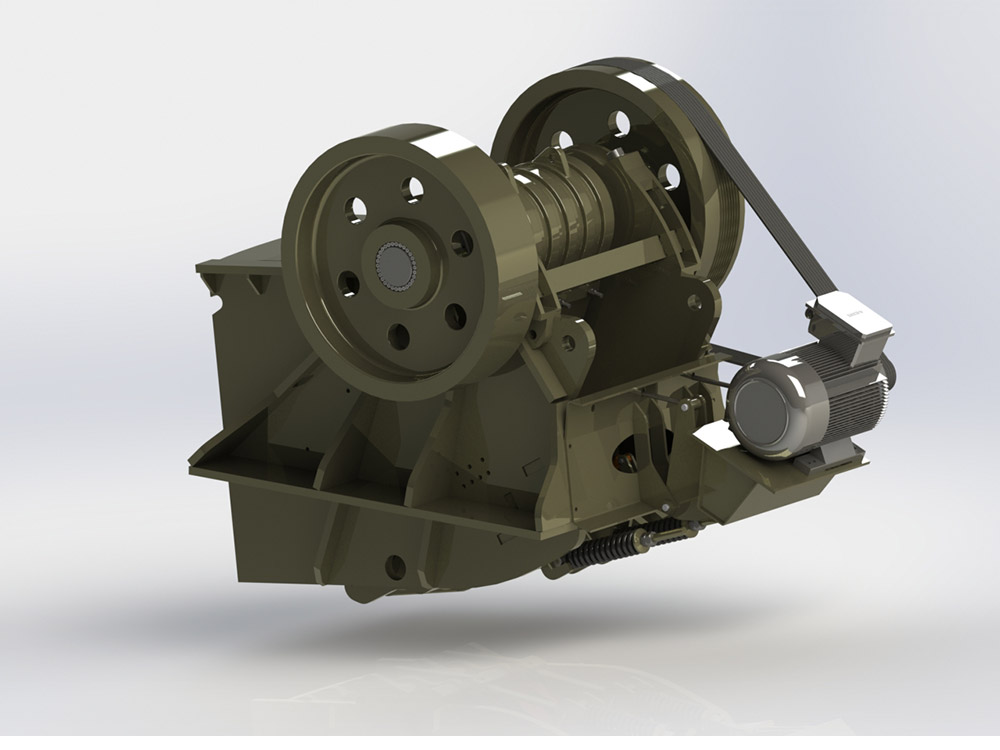

CESA jaw crushers are designed to crush all kinds of materials, from soft limestone to the hardest basalt. We have 6 different types of Primary and Secondary jaw crushers from 610 x 380 mm type to 1300 x 1100 mm mouth opening.

The high performance, reliability, durability and user-friendly adjustment mechanisms of our jaw crushers due to their high flywheel speeds, jaw grabbing angles, special geometries of their pits with safety plates and rear blocks provide unique operating advantages to its users.

All CESA jaw crushers are equipped with hydraulic assist adjustment mechanism. This system allows the jaw bottom opening to be adjusted easily and quickly according to the product curve you want to buy from the machine.

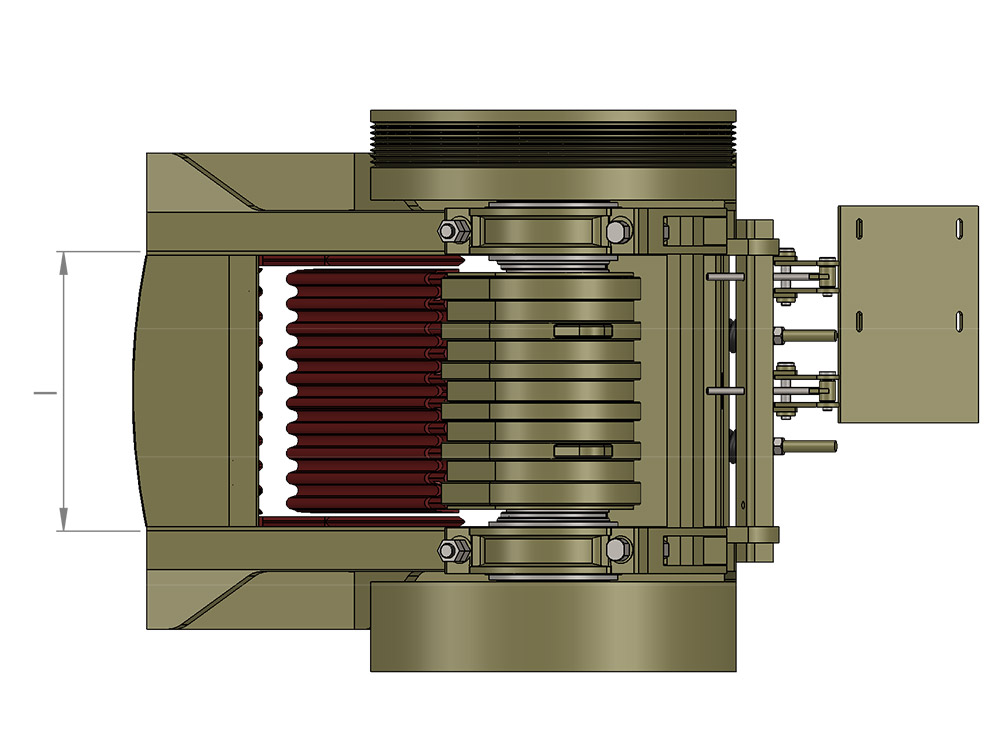

The flywheel hubs of our large jaw crushers (CJC-110 1100 x 850 and CJC-90 900 x 650) are equipped with a special clamping system that connects the flywheels to the camshaft. This system allows the flywheel to hold the shaft securely and tightly in the case of excessive strain during restarting caused by the rocks remaining in the jaw mouth as a result of stopping the machine for any reason. It also facilitates the disassembly-assembly operations that may be required for maintenance and transportation.

Crushers are equipped with an automatic lubrication system optionally.

Pitman is made of steel section and is designed to meet the contraction loads that will occur even under the most severe conditions.

MAIN FEATURES

| MODEL | TOTAL CAPACITY | ENGINE POWER | JAW DIMENSIONS |

|---|---|---|---|

K-02 |

50-60 ton/s |

30 kW |

610x380 mm |

K-03 |

140-160 ton/s |

75 kW |

900x650 mm |

K-07 |

250-300 ton/s |

132 kW |

1100x850 mm |

K-11 |

400-450 ton/s |

160 kW |

1300x1000 mm |

TECHNICIAL SPECIFICATIONS

| MODEL | TOTAL CAPACITY | ENGINE POWER | JAW DIMENSIONS |

|---|---|---|---|

K-04 |

50-60 ton/s |

30 kW |

900x200 mm |

K-12 |

140-160 ton/s |

55 kW |

1100x350 mm |

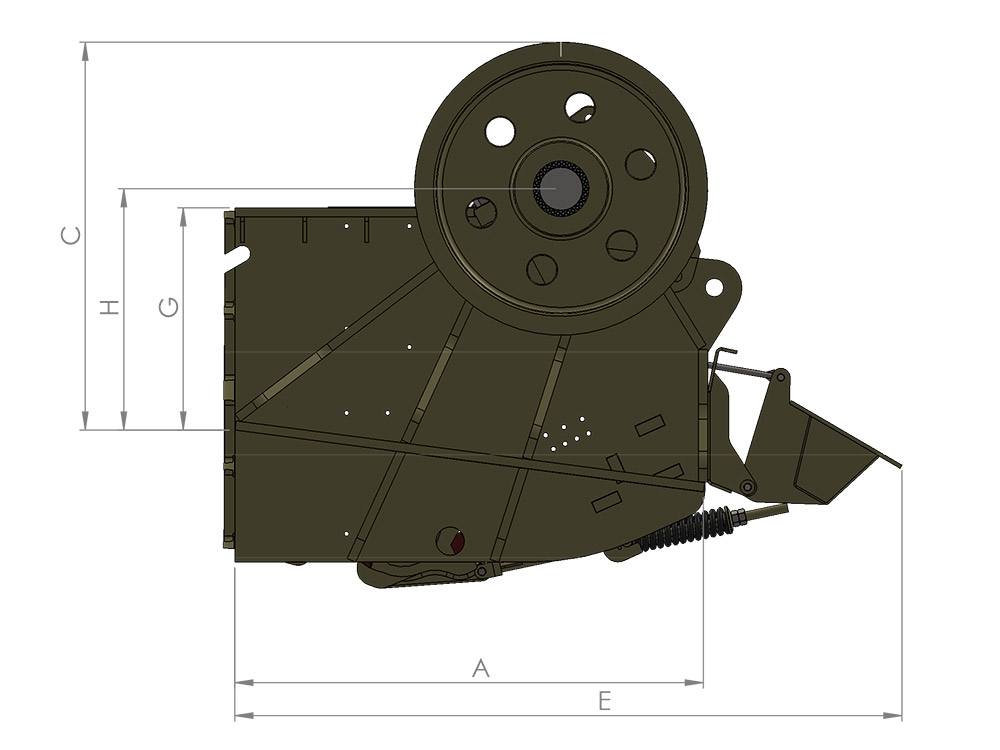

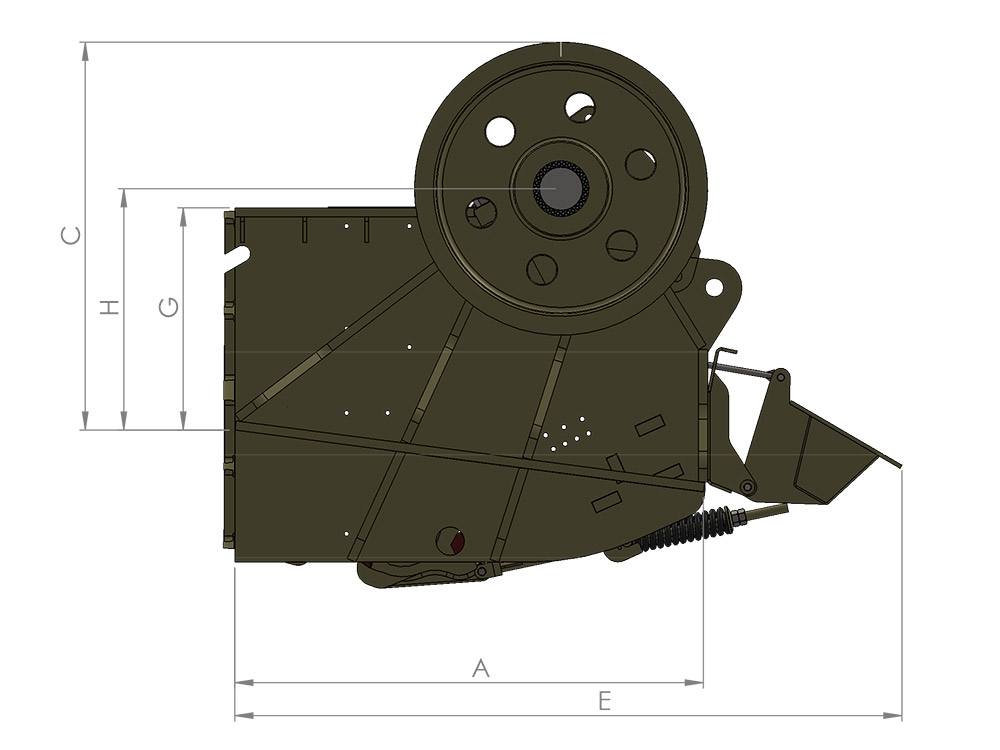

| A | B | C | D | E | F | G | H | I | |

|---|---|---|---|---|---|---|---|---|---|

K-02 |

1700 |

1608 |

2210 |

1200 |

2106 |

2070 |

1241 |

1605 |

988 |

K-3 |

2380 |

1735 |

2822 |

2365 |

2500 |

2300 |

1240 |

1500 |

980 |

K-07 |

2580 |

2086 |

2542 |

1600 |

3635 |

2460 |

1202 |

1538 |

1190 |

K-11 |

3070 |

1780 |

3470 |

1800 |

3070 |

2820 |

2590 |

2570 |

1340 |

K-04 (SECONDARY) |

2380 |

1735 |

2822 |

2365 |

1382 |

3330 |

800 |

1860 |

765 |

K-12 (SECONDARY) |

2380 |

1735 |

2822 |

2365 |

1382 |

3330 |

800 |

1860 |

1010 |